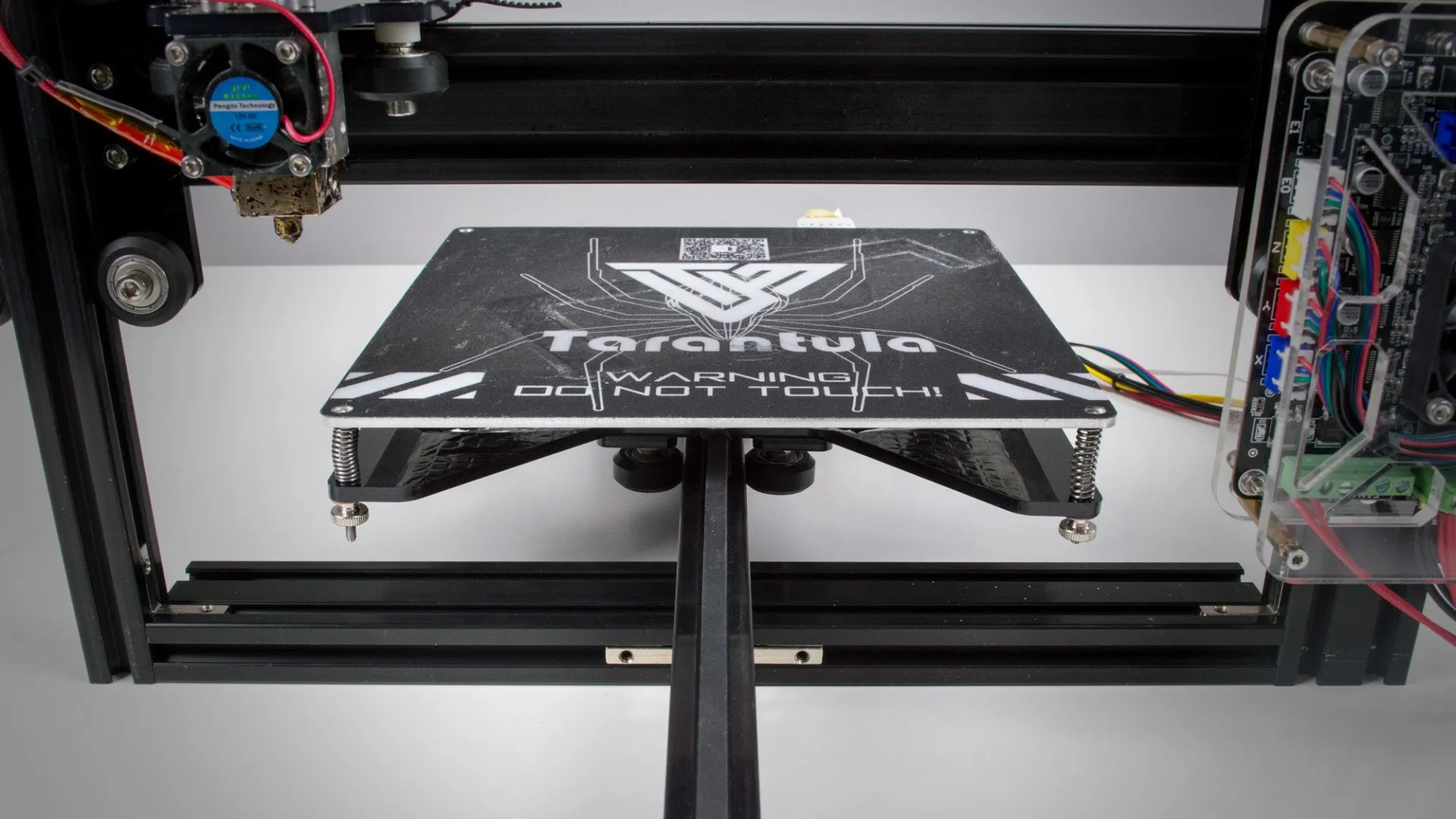

The Tevo Tarantula is a popular and affordable 3D printer, but its stock hotend can be a limiting factor for achieving high-quality prints and using a wide variety of filaments. Upgrading to an e3d v6 hotend is a significant improvement that can unlock the full potential of your Tevo Tarantula. This guide will walk you through the entire process, from gathering the necessary components to configuring your printer’s firmware and troubleshooting common issues, ensuring you get the best possible results from your upgrade.

Why Upgrade Your Tevo Tarantula with an e3d v6?

The e3d v6 is a high-performance hotend renowned for its superior thermal performance and versatility. It’s a worthwhile upgrade for any Tevo Tarantula owner seeking to enhance their 3D printing experience. The stock hotend, while functional, often struggles with precise temperature control, limiting the types of materials you can use and the quality of your prints. An e3d v6 offers several key advantages, resulting in a more reliable and enjoyable printing experience.

Improved Print Quality

The e3d v6’s all-metal design allows for more precise temperature control, leading to smoother surfaces, finer details, and reduced stringing and oozing. The improved thermal stability ensures consistent filament flow, minimizing imperfections and enhancing overall print quality. This leads to the ability to print complex designs with greater accuracy and a professional finish. With better temperature control and a more efficient heat break, the e3d v6 delivers cleaner and sharper prints than the stock hotend.

Wider Filament Compatibility

The e3d v6’s ability to reach higher temperatures opens the door to a wider range of filaments, including high-temperature materials like ABS, nylon, and polycarbonate. This expands your creative possibilities, allowing you to print stronger, more durable parts and experiment with different colors and finishes. The improved thermal management of the e3d v6 prevents filament jams and clogs, further enhancing your filament compatibility. This allows you to explore the full spectrum of 3D printing materials available.

Enhanced Temperature Control

The e3d v6 features a more efficient heating system and a precise thermistor, resulting in superior temperature regulation. This is critical for consistent filament extrusion and optimal print quality. Precise temperature control also reduces the risk of thermal runaway, a safety feature that can prevent your printer from overheating. The advanced design of the e3d v6 ensures accurate and stable temperatures, resulting in reliable prints and a more stable printing process.

What You’ll Need for the e3d v6 Upgrade

Before you begin, gather the following components and tools. Having everything ready will streamline the installation process and minimize downtime. Some of these items might be specific to the Tevo Tarantula, so make sure you have the correct parts.

e3d v6 Hotend

Purchase a genuine e3d v6 hotend kit. Make sure you get the 1.75mm filament version, which is standard for most 3D printers. The kit typically includes the heatsink, heat break, heater block, nozzle, and associated screws and connectors. You can usually find these kits on the e3d website or through authorized resellers. Ensure the nozzle size is appropriate for your typical print settings, generally 0.4mm is a good starting point.

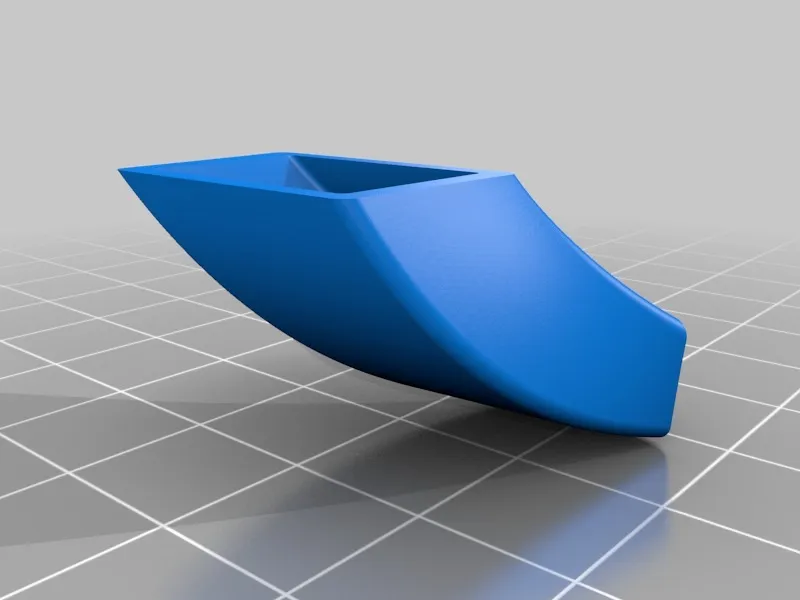

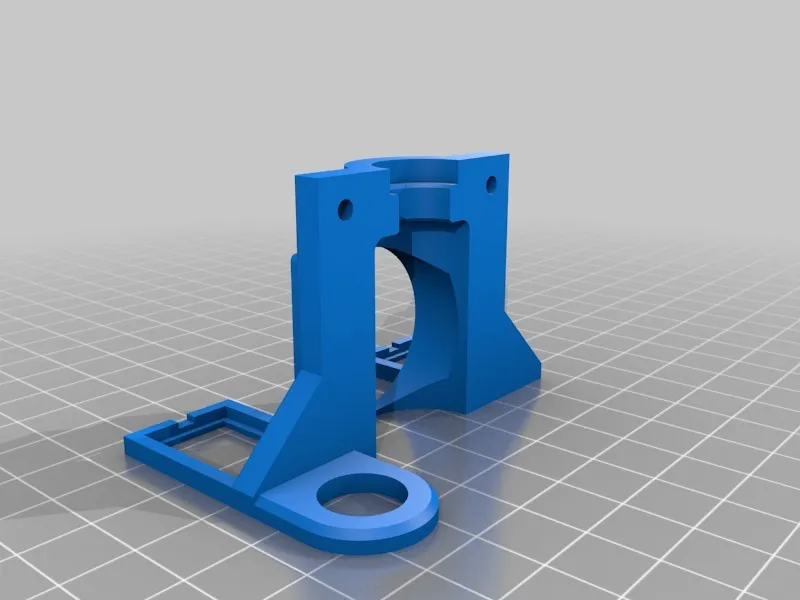

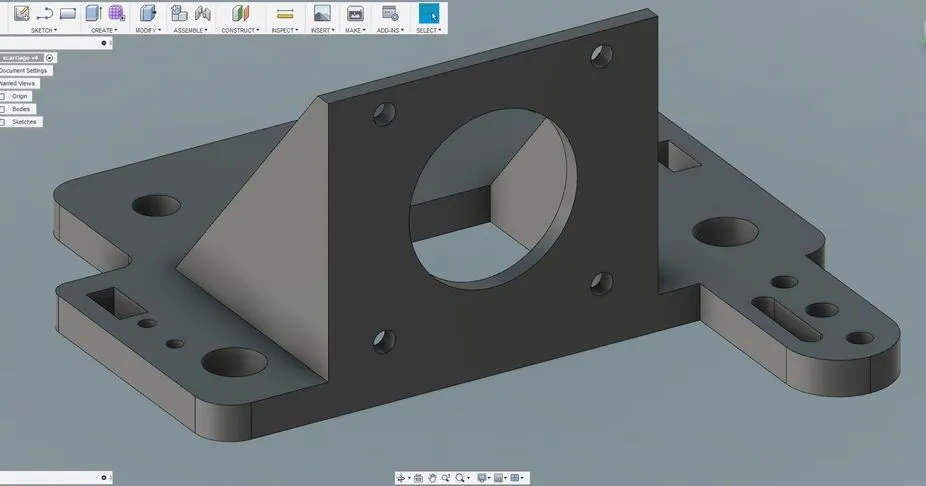

Tevo Tarantula Mount Adapter

You’ll need a mount adapter specifically designed to attach the e3d v6 to your Tevo Tarantula’s X-carriage. This adapter ensures the e3d v6 is securely mounted and properly aligned. These adapters are often available for purchase online or can be 3D printed. Make sure to choose an adapter that fits your specific Tevo Tarantula model.

Tools Required

- Screwdrivers (various sizes)

- Allen wrenches (hex keys)

- Wire cutters/strippers

- Soldering iron (optional, for wiring)

- Multimeter (for checking connections)

- Heat-resistant tape (Kapton or similar)

- 3D printer bed adhesive (e.g., glue stick or hairspray)

- Calipers (for measuring dimensions)

Step-by-Step e3d v6 Installation Guide

Follow these steps to install your e3d v6 hotend on your Tevo Tarantula. Take your time, double-check connections, and consult the e3d v6 documentation for additional details. It’s also helpful to take pictures at each step to help you remember the process.

Disassembly of the Old Hotend

Turn off and unplug your 3D printer. Carefully remove the existing hotend assembly from your Tevo Tarantula’s X-carriage. Disconnect all wires, including the heater cartridge and thermistor, and remove any screws or clamps holding the hotend in place. Be careful not to damage any wires or components during this process. Take pictures before each step to help you remember how everything was connected.

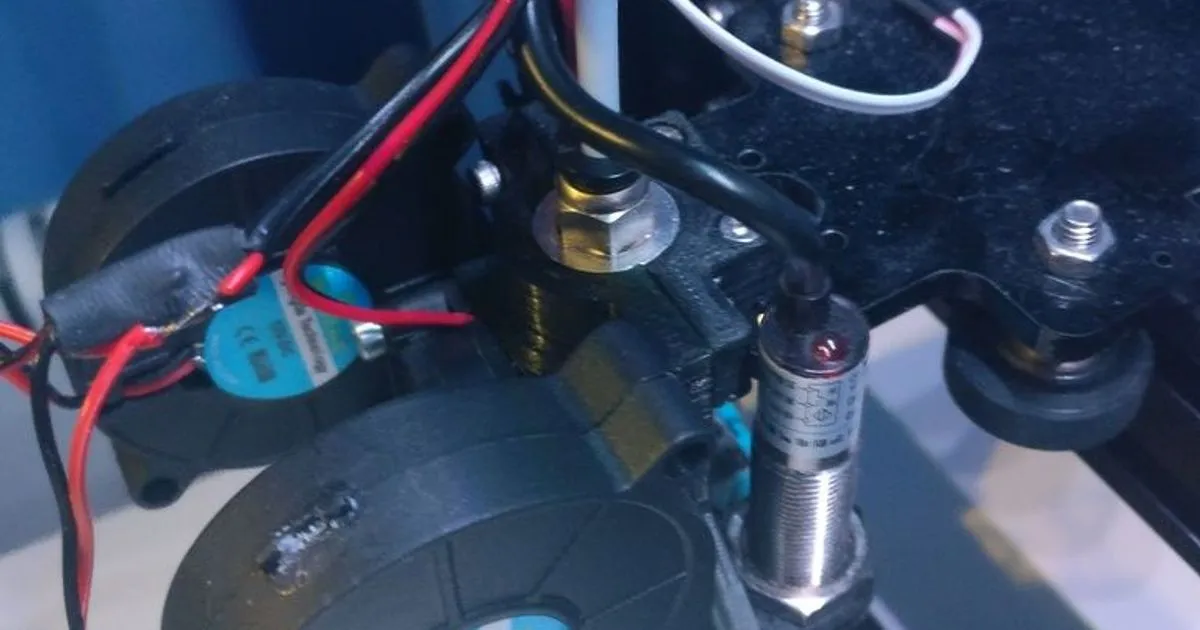

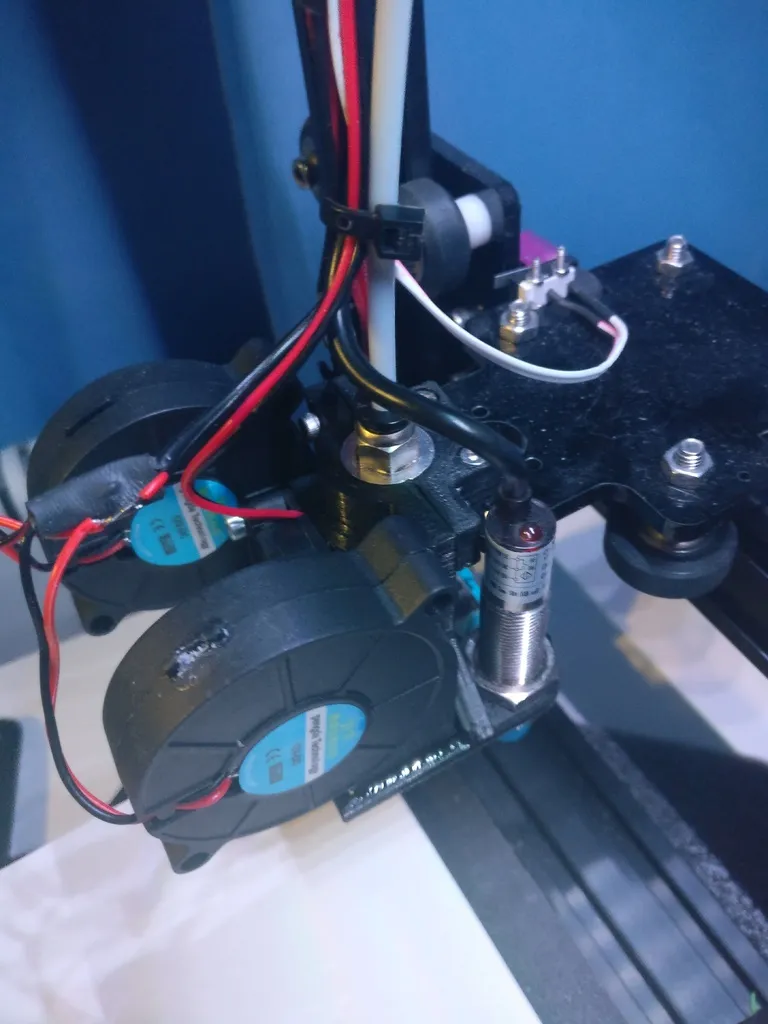

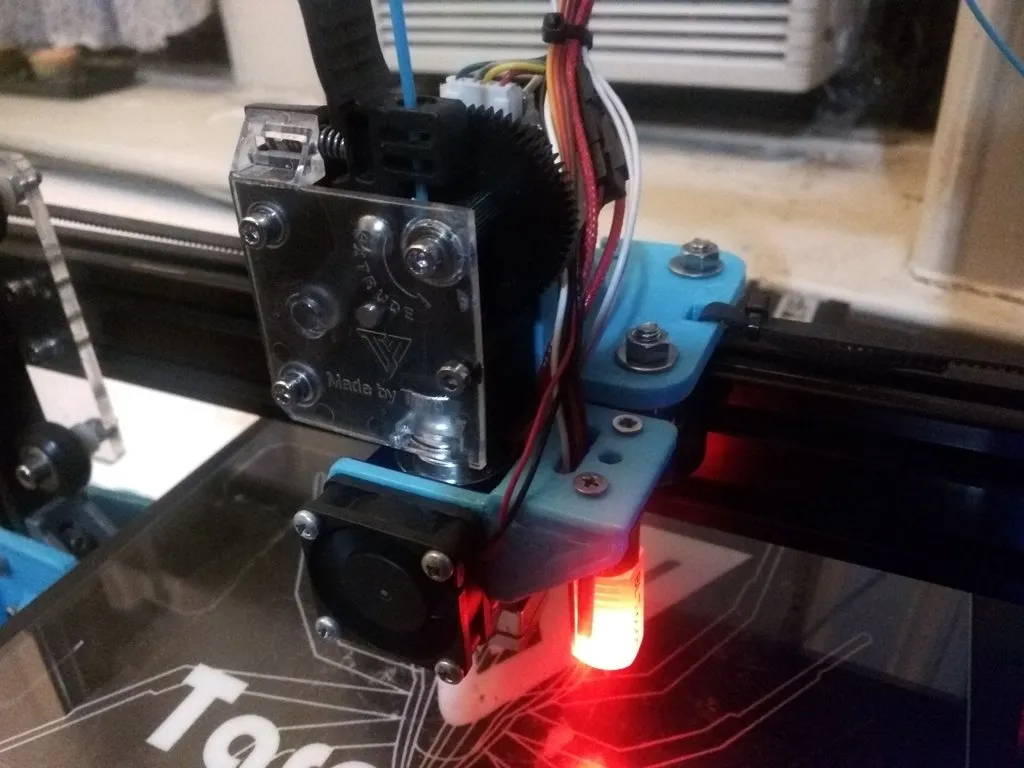

Mounting the e3d v6

Attach the e3d v6 hotend to the mount adapter, following the adapter’s instructions. Securely fasten the adapter to the X-carriage. Ensure the nozzle is properly aligned and that the hotend is firmly mounted. Double-check that the nozzle is facing downwards and that the entire assembly is stable. Tighten all screws securely, but avoid overtightening.

Wiring the e3d v6

Connect the heater cartridge and thermistor wires to your printer’s control board. You may need to crimp or solder the wires, depending on your printer’s setup. Ensure that the polarity of the heater cartridge is correct (usually not important, but check your control board documentation) and that the thermistor is properly connected. Secure the wires to prevent them from interfering with the printer’s movement.

Connecting the Thermistor

Connect the thermistor to the control board, ensuring that it is correctly wired. The thermistor measures the temperature of the hotend, so it is essential for proper temperature control. Secure the thermistor wires to prevent them from moving or breaking. Make sure the thermistor is in close contact with the heater block and not shorting against anything.

Connecting the Heater Cartridge

Connect the heater cartridge wires to the control board, ensuring that they are securely connected. The heater cartridge is responsible for heating the hotend. Double-check the wiring and polarity to prevent issues. Make sure the heater cartridge is in good contact with the heater block, to ensure efficient heating.

Firmware Configuration Adjustments

After installing the e3d v6, you’ll need to adjust your printer’s firmware settings to match the new hotend. This is a critical step to ensure proper temperature control and prevent print failures. The process involves adjusting e-steps, PID tuning, and potentially bed leveling.

Adjusting E-steps

E-steps (extruder steps per millimeter) control the amount of filament your extruder pushes through the hotend. You’ll need to calibrate your e-steps for the e3d v6. First, heat the hotend to your printing temperature, then measure and mark 100mm of filament above the extruder. Extrude 100mm of filament through the hotend, then measure how much filament remains above the extruder. Use the formula to calculate the new E-steps: New E-steps = (Current E-steps * 100) / (100 – Remaining Filament). Update the E-steps value in your printer’s firmware.

PID Tuning

PID (Proportional, Integral, Derivative) tuning optimizes the temperature control of your hotend. PID tuning ensures the hotend reaches and maintains the target temperature accurately. You can perform PID tuning through your printer’s control panel or with dedicated software (like Pronterface). Follow the instructions specific to your firmware (Marlin, etc.) to perform the auto-tune process. Save the new PID values to your printer’s firmware.

Bed Leveling and Calibration

Since the nozzle height may have changed, re-level your print bed. Use the paper test or your printer’s auto-leveling feature to ensure proper nozzle-to-bed distance. Also, calibrate your first layer height to ensure good adhesion. This step ensures that the initial layers adhere properly to the print bed. Print a test print, such as a calibration cube, and make any necessary adjustments to the bed leveling or Z-offset settings.

First Print and Troubleshooting

Once you’ve completed the installation and firmware adjustments, it’s time to test your new setup. Start with a simple print, like a calibration cube, and carefully monitor the print quality. Be prepared to troubleshoot any issues that may arise.

Common Issues and Solutions

If you encounter problems during your first print, consult the following troubleshooting tips:

- Filament not extruding: Check for clogs in the nozzle, incorrect temperature settings, or extruder issues.

- Poor bed adhesion: Re-level the bed, clean the bed surface, and use bed adhesive (glue stick or hairspray).

- Stringing or oozing: Adjust retraction settings and reduce printing temperature.

- Under-extrusion: Recalibrate e-steps and increase the flow rate.

- Over-extrusion: Reduce the flow rate.

- Temperature fluctuations: Retune PID values.

Fine-tuning Print Settings

After the first print, fine-tune your print settings for optimal results. Experiment with different print temperatures, print speeds, and retraction settings to achieve the desired print quality. Consider factors like layer height, infill density, and cooling settings. Review and adjust your settings based on the filament type you’re using. Proper calibration and experimentation will help you unlock the full potential of the e3d v6.

Benefits of the e3d v6 Upgrade

The e3d v6 upgrade offers significant improvements over the stock hotend, leading to better prints, increased material options, and greater reliability. The investment is worthwhile for anyone looking to improve their 3D printing experience.

Print Quality Improvements

Expect to see a noticeable improvement in the print quality, with smoother surfaces, finer details, and reduced imperfections. The e3d v6’s thermal stability and precise temperature control contribute to consistent and reliable prints. With careful calibration and settings adjustments, you’ll be able to achieve professional-looking results with your Tevo Tarantula and the e3d v6.

Material Versatility

The e3d v6 enables you to print a wider range of materials, opening up new possibilities for your 3D printing projects. You’ll be able to experiment with various types of filaments, including those that require higher printing temperatures. Expand your creative horizons and explore new materials with confidence.

Long-term Reliability and Maintenance

The e3d v6 is a robust and reliable hotend designed for long-term use. Regular maintenance, such as cleaning the nozzle and checking for leaks, will help maintain its performance. With proper care, the e3d v6 will provide years of dependable service and enhance your 3D printing experience. Investing in a high-quality hotend like the e3d v6 can lead to a more reliable and enjoyable experience in the long run.

By following this comprehensive guide, you can successfully upgrade your Tevo Tarantula with an e3d v6 hotend and unlock its full potential. Enjoy the improved print quality, wider material compatibility, and enhanced reliability that the e3d v6 offers. Happy printing!