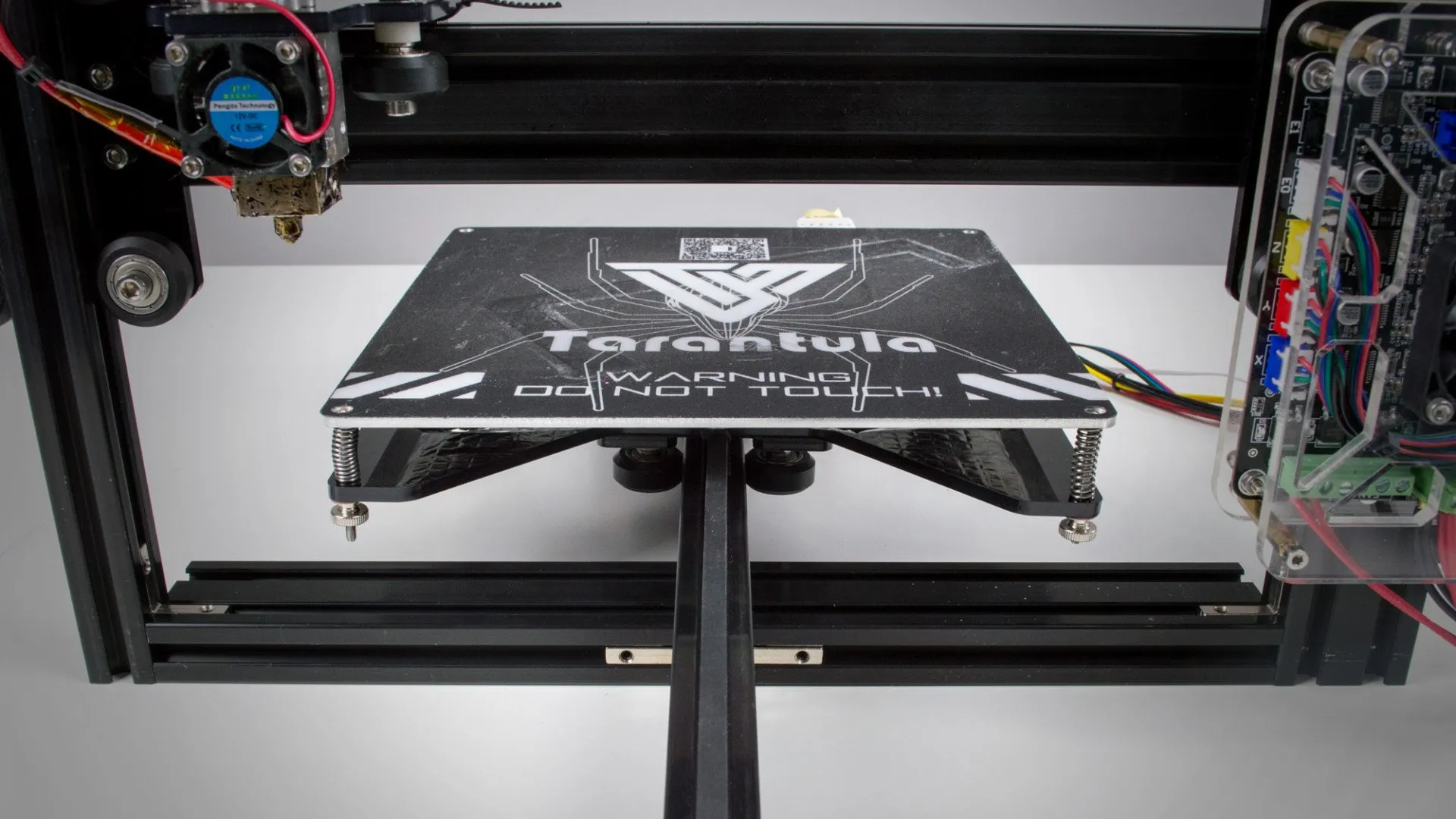

Upgrading your Tevo Tarantula 3D printer’s bed to an aluminum variant is a smart move for any enthusiast looking to enhance print quality, reliability, and overall user experience. The stock bed, while functional, can be improved upon. This guide dives into the top five benefits of making this upgrade, providing you with the knowledge you need to make an informed decision. From improved bed leveling to increased printing success, the advantages are significant. Let’s explore why switching to an aluminum bed is a worthwhile investment for your Tevo Tarantula.

Why Upgrade Tevo Tarantula Bed to Aluminum?

The primary reason for upgrading your Tevo Tarantula’s bed to aluminum is to address the limitations of the original design. The stock bed often suffers from issues like uneven heating and warping, which can lead to print failures and frustration. An aluminum bed offers a more stable and reliable surface, ensuring that your prints adhere properly and that the first layer is consistently laid down. Furthermore, aluminum beds are generally more durable and resistant to wear and tear, providing a long-term solution for improved print quality and ease of use. Choosing an aluminum bed is a proactive step towards optimizing your 3D printing workflow and achieving professional-grade results. This upgrade will solve several issues and enhance the overall printing experience.

Improved Bed Leveling

Bed leveling is crucial for successful 3D printing. An aluminum bed provides a flat, stable surface that is far easier to level than the stock bed, which may be prone to flexing or warping. With a rigid aluminum bed, you can achieve a consistent distance between the nozzle and the print surface across the entire bed area. This consistency is essential for proper first-layer adhesion and reduces the likelihood of the nozzle being too close or too far from the bed, leading to print failures. The flatness of an aluminum bed minimizes the need for constant adjustments, saving you time and effort. This flatness is critical for the initial layer, where adhesion is key to a successful print, and contributes significantly to your overall printing experience.

Enhanced Heat Distribution

Aluminum is an excellent conductor of heat, ensuring that the bed heats up quickly and evenly. This uniform heat distribution is essential for materials like ABS, which require consistent temperatures to prevent warping. Unlike the stock bed, which may have hot spots or uneven heating, an aluminum bed ensures that the entire print surface reaches the set temperature consistently. This uniform temperature control minimizes the risk of warping and allows for better adhesion of the first layer. By providing consistent heating, an aluminum bed significantly improves the reliability and quality of your prints, particularly when working with temperature-sensitive filaments. This feature is very important for getting good results.

Superior Durability

The stock bed may degrade over time, especially with repeated use and exposure to high temperatures. An aluminum bed is much more durable and can withstand the rigors of continuous 3D printing. Aluminum is resistant to scratches, warping, and other forms of wear and tear. This durability means the bed will maintain its flatness and heating properties for longer, saving you money and reducing the need for frequent replacements. The robust nature of an aluminum bed ensures that it will last, providing a reliable surface for all your printing projects. With aluminum, you are investing in a long-term solution for your 3D printing needs.

Reduced Warping

Warping is a common issue in 3D printing, particularly with materials like ABS and PETG. An aluminum bed helps to minimize warping by providing a stable, evenly heated surface. The uniform heat distribution prevents the edges of the print from cooling too quickly, which is a primary cause of warping. The flatness and rigidity of the aluminum bed also contribute to reduced warping by ensuring that the print adheres properly to the surface. By mitigating warping, an aluminum bed significantly increases the success rate of your prints and allows you to work with a wider range of materials. The reduction in warping is a major benefit that improves print quality and overall satisfaction.

Increased Printing Success

All of the benefits discussed above – improved bed leveling, enhanced heat distribution, superior durability, and reduced warping – ultimately lead to a higher success rate for your prints. With an aluminum bed, you’ll experience fewer failed prints, reduced material waste, and a more enjoyable 3D printing experience. The consistent performance and reliability of an aluminum bed allow you to focus on creating and experimenting, rather than troubleshooting print failures. The increased success rate means that you can rely on your printer to produce high-quality results, time after time. It is an investment that pays off with every successful print.

How to Install Aluminum Bed

Tools Needed

Before you start, gather the necessary tools. You’ll typically need a hex key set, a screwdriver, and possibly a wrench. Ensure you have the correct size hex keys for your printer’s screws. A digital caliper can be helpful for precise measurements. Also, have your new aluminum bed and any mounting hardware that came with it ready. Check your printer’s manual for any specific tools recommended. A good quality set of tools will make the installation process smoother and more efficient. It’s always a good idea to double-check that you have everything before you begin.

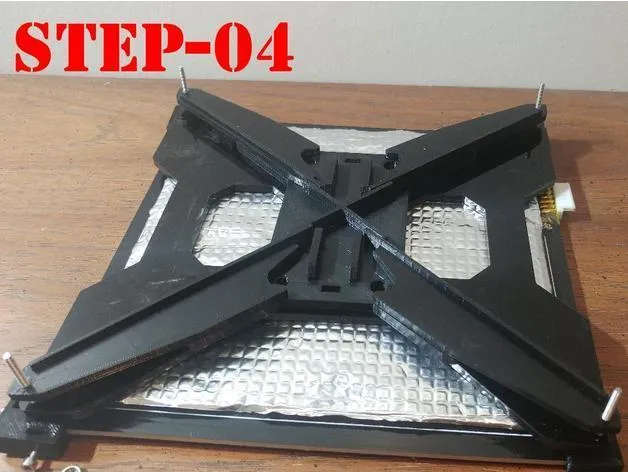

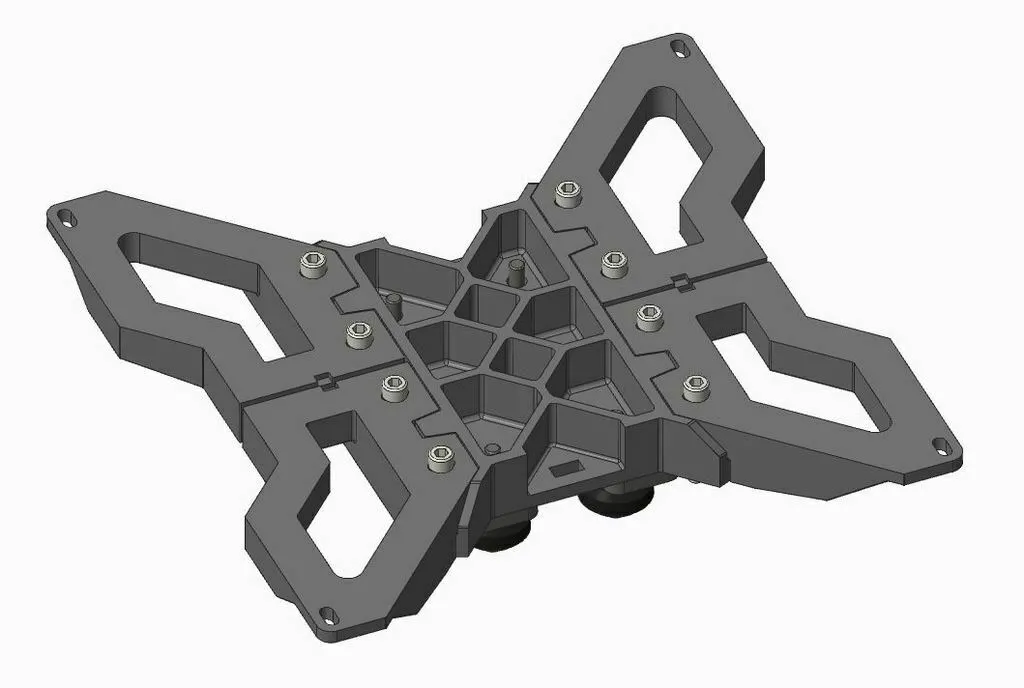

Step-by-Step Installation Guide

Follow these steps to install your new aluminum bed Replace the existing bed. Carefully detach the old bed from your Tevo Tarantula, making sure to disconnect any wiring for the heated bed. Then, install the new aluminum bed. Align the aluminum bed with the existing mounting holes on the printer’s frame. Secure the bed with the screws provided. Check the wiring. Make sure you connect the heated bed wires correctly. Level the bed. Use the leveling screws to adjust the bed’s height until it is perfectly level with the nozzle. Test the heating. Turn on the printer and test the bed’s heating function to ensure it heats up evenly. Fine-tune the settings. Adjust your printer’s settings to match the new bed’s specifications. Consult the provided manual for specific instructions. By following these steps, you can successfully upgrade your Tevo Tarantula’s bed and enjoy improved printing performance.

Where to Buy Aluminum Bed

Cost and Budgeting

Aluminum beds for the Tevo Tarantula are available at various price points. The cost typically depends on the size, quality, and any included accessories. Budget-friendly options can be found for around $20-$40, while higher-end models might cost more. When budgeting, consider not only the bed itself but also any additional hardware you might need, such as mounting brackets or leveling springs. Always check the specifications to ensure the bed is compatible with your Tevo Tarantula model. Researching different options allows you to find a good value that meets your printing needs without breaking the bank. Do the comparison to find the right product.

Top Recommended Aluminum Beds

When shopping for an aluminum bed for your Tevo Tarantula, consider reputable brands and models known for quality and reliability. Research online marketplaces like Amazon, eBay, and specialized 3D printing supply stores. Look for beds made from high-quality aluminum with a flat and even surface. Read reviews from other Tevo Tarantula owners to get feedback on the bed’s performance and ease of installation. Some popular choices include beds that come pre-drilled with mounting holes for easier setup. Check for features such as built-in thermal fuses for safety. Comparing different options will help you find an aluminum bed that provides excellent value and enhances your printing experience.

Maintaining Your Aluminum Bed

Cleaning and Maintenance Tips

Regular cleaning and maintenance will help keep your aluminum bed in top condition. After each print, clean the bed surface to remove any residue from the filament or adhesive. Use a soft cloth or a scraper to gently remove any remaining material. Avoid using abrasive cleaners that could scratch the surface. Before each print, ensure the bed is level. Check for any damage, like scratches or dents, and address them as needed. Make sure to keep the bed clean to improve print adhesion and ensure good results. The regular care will make your prints better.

Troubleshooting Common Issues

Even with an aluminum bed, you might encounter some issues. Poor adhesion can be a problem. Ensure the bed is properly leveled, and the first layer is properly squished. Check your nozzle height. If prints are not sticking, consider using an adhesive such as glue stick or hairspray to help with adhesion. If the bed isn’t heating correctly, check the wiring connections and ensure the thermistor is functioning properly. For uneven heating, ensure the power supply is adequate, and the bed surface is clean. Always consult the printer’s manual for troubleshooting guidance. By being aware of common problems, you can keep your printer working properly.

In conclusion, upgrading your Tevo Tarantula with an aluminum bed offers numerous benefits. From improved print quality and reliability to increased success rates and ease of use, this is a worthwhile investment. By following the installation guide, choosing a quality bed, and maintaining it properly, you can significantly enhance your 3D printing experience. Consider the positive impact an aluminum bed can have on your prints, and enjoy the benefits of a well-equipped 3D printer.