What Causes Extruder Clicking on the Tevo Tarantula

The Tevo Tarantula, a popular DIY 3D printer, can sometimes exhibit an annoying problem known as extruder clicking. This sound indicates that the extruder motor is struggling to push filament through the nozzle. Understanding the root causes of this issue is the first step in resolving it and getting back to printing smoothly. Extruder clicking often leads to print failures, so identifying and addressing the problem promptly is essential for successful 3D printing projects. This guide will help you understand the common causes and how to fix this issue. The clicking sound itself is usually the motor skipping or grinding, unable to advance the filament.

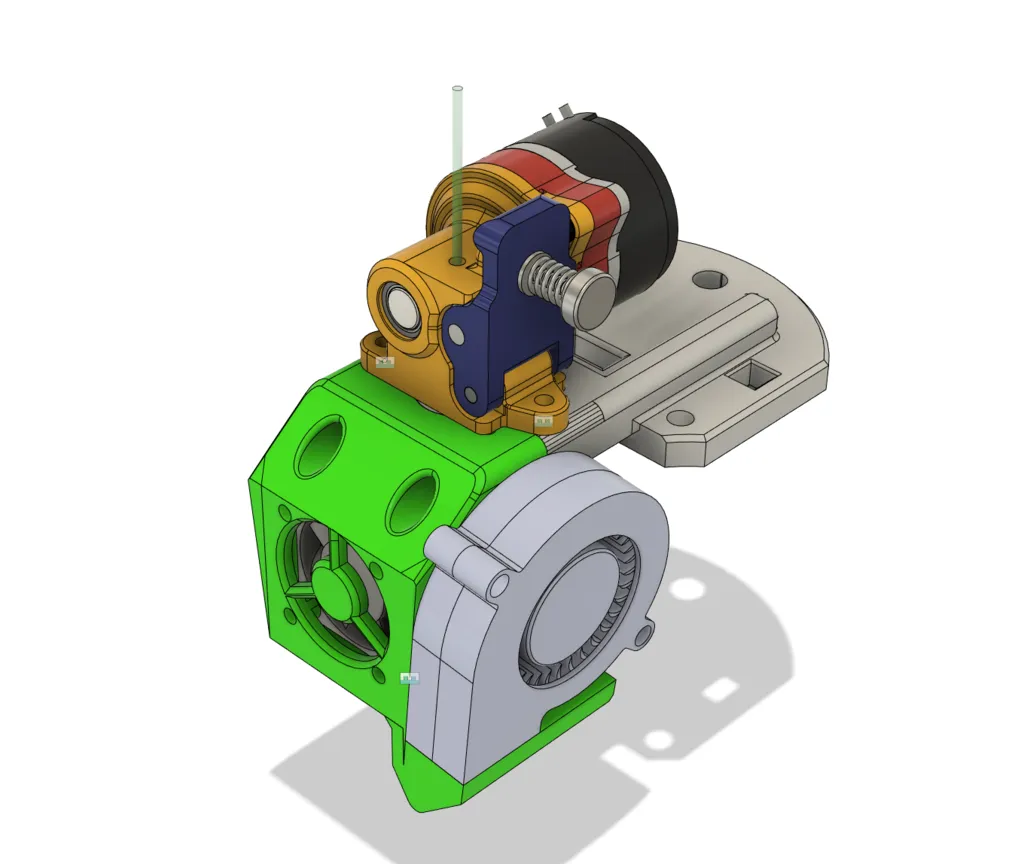

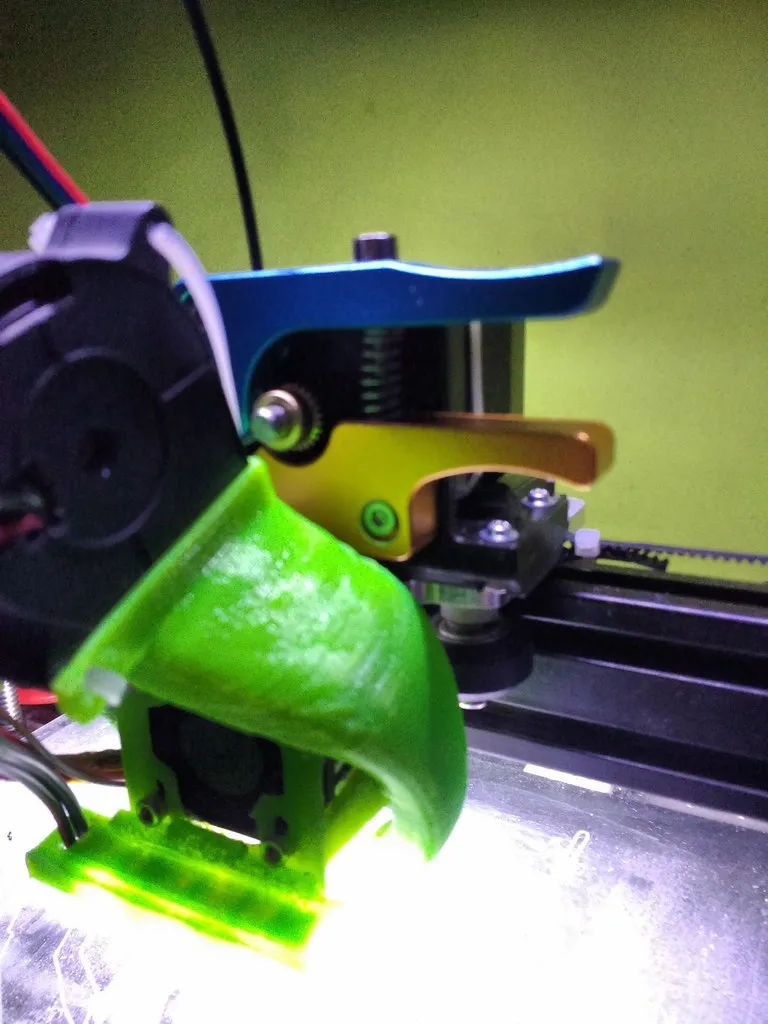

Understanding the Extruder’s Role

The extruder is a critical component of any 3D printer, including the Tevo Tarantula. Its primary function is to feed the filament into the hot end, where it melts and is deposited onto the print bed. The extruder consists of a motor, a hobbed gear, and a drive gear. The hobbed gear grips the filament and pushes it forward, while the drive gear provides the necessary torque. When the extruder clicks, it means this process is interrupted, and the filament isn’t being fed consistently, which causes print defects. Proper functioning of the extruder is vital for layer adhesion and overall print quality. A well-maintained extruder will ensure consistent and reliable 3D printing results.

Common Causes of Clicking

Extruder clicking can stem from various issues. The most common include problems with the filament itself, a clogged nozzle, or incorrect temperature settings. Other factors, such as insufficient extruder motor power, can also contribute. Diagnosing the specific cause is crucial for applying the correct fix. Troubleshooting involves checking several areas, starting with the simplest and most common issues. It’s important to address these issues systematically to prevent print failures. A systematic approach helps identify the root cause quickly and efficiently.

Filament Issues

Filament plays a significant role in extruder clicking. Sometimes, the filament itself may be to blame. Common problems include tangled filament on the spool, which restricts feeding. Inconsistent filament diameter can cause the extruder to work harder, leading to clicking. Additionally, moisture absorbed by the filament can cause it to expand and clog the nozzle, triggering clicking. Always inspect your filament before printing, ensuring it feeds smoothly and has no visible defects. Using a filament dryer can help if you suspect moisture is the issue. Choose high-quality filaments from trusted brands to minimize these problems. (Image: filament-issues.webp)

Clogged Nozzle

A clogged nozzle is a frequent culprit behind extruder clicking. When the nozzle is blocked, the extruder motor struggles to push the filament through the obstruction. This blockage can result from filament degradation, dust particles, or incorrect printing temperatures. To fix this, try using a needle or a specialized nozzle cleaning tool to remove the clog. Heating the nozzle to a high temperature (but within the filament’s safe range) can help soften the plastic, making it easier to clear. Performing a ‘cold pull’ by manually extracting the filament after cooling can also pull out debris. Regular nozzle maintenance is a crucial aspect of 3D printer care. (Image: clogged-nozzle.webp)

Incorrect Temperature Settings

Temperature plays a critical role in 3D printing. If the nozzle temperature is too low, the filament won’t melt sufficiently, leading to increased resistance and clicking. Conversely, if the temperature is too high, the filament may degrade, causing blockages or inconsistent extrusion. Check the recommended temperature range for your specific filament type and adjust your printer settings accordingly. A good starting point is to experiment with temperatures within the recommended range, increasing or decreasing in small increments until you achieve optimal print quality. Monitoring the filament flow during printing is crucial for fine-tuning the temperature. (Image: adjusting-temperature.webp)

How to Troubleshoot Tevo Tarantula Extruder Clicking

Troubleshooting extruder clicking involves a systematic approach. Begin by visually inspecting your setup and then move on to more in-depth checks. The key is to methodically eliminate potential causes. Proper troubleshooting can help you quickly identify and fix the issue. Having the right tools can make troubleshooting much easier. The troubleshooting steps below will guide you through a process of elimination, helping you pinpoint the source of the problem. This approach saves time and reduces frustration, leading to more successful prints.

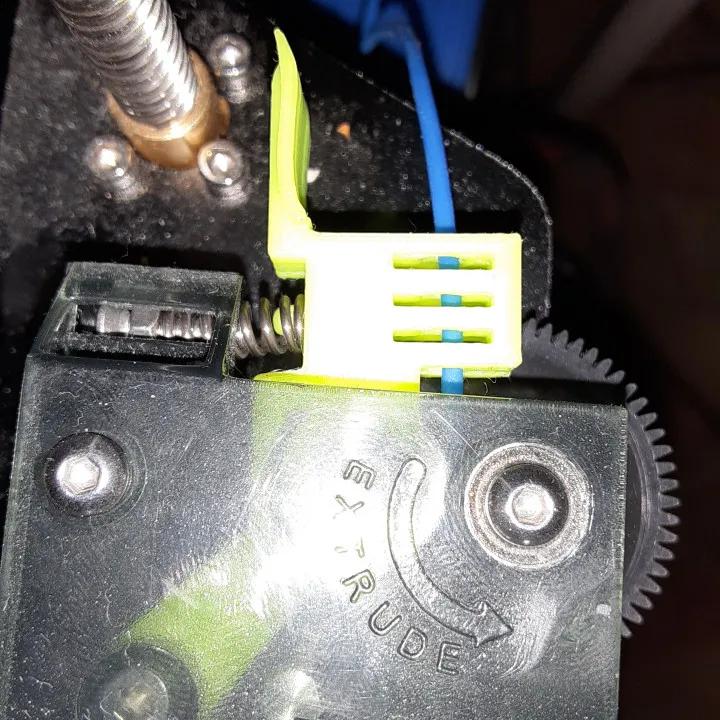

Checking the Filament

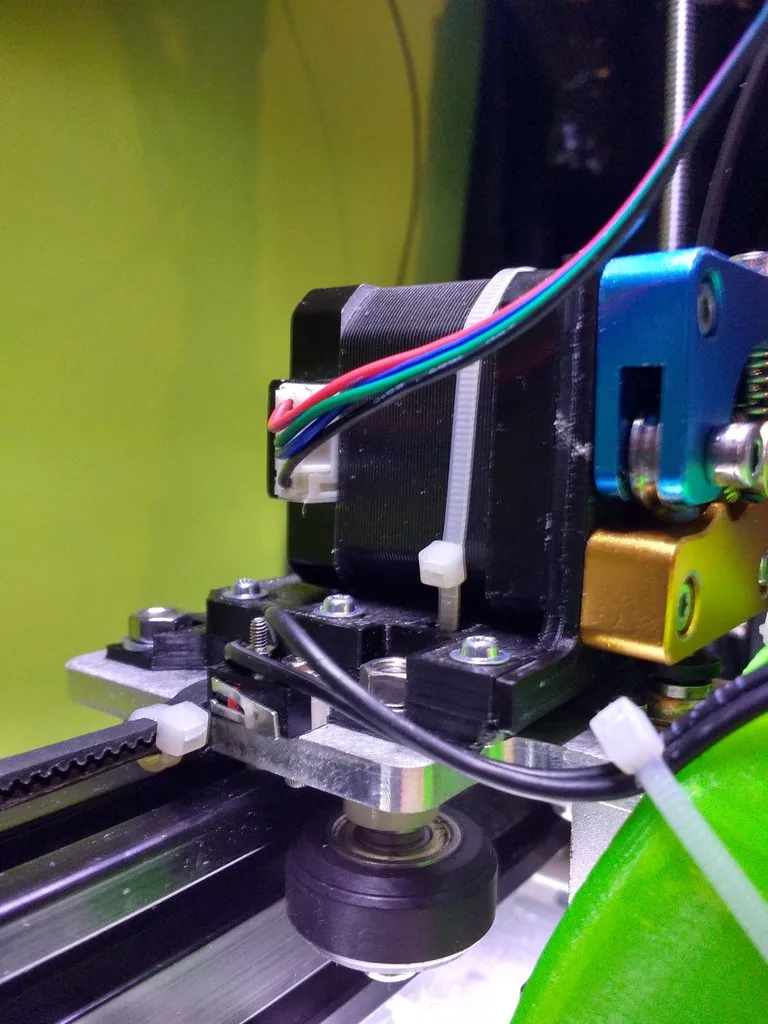

Start by examining the filament. Ensure it’s feeding smoothly from the spool without any tangles. Check the filament diameter and if the filament is dry. Unspool a small length and inspect for any inconsistencies or breaks. If you find tangles or knots, carefully unwind and respool the filament. If the filament has absorbed moisture, consider using a filament dryer before printing. A simple visual inspection can often reveal the source of the problem. Make sure the filament spool holder allows for smooth rotation, which helps to prevent feeding issues. (Image: tevo-tarantula-extruder.webp)

Clearing a Clogged Nozzle

If you suspect a clogged nozzle, heat the hot end to the recommended temperature for your filament. Once heated, manually push filament through the nozzle to see if it extrudes smoothly. If not, use a needle or a specialized nozzle cleaning tool to clear the blockage. Another method is to perform a ‘cold pull’. After heating the nozzle, let it cool down slightly, then manually extract the filament. This can often pull out debris. You may need to repeat this process multiple times. Regular nozzle cleaning is essential for maintaining consistent print quality and preventing clicking. Be careful when working with hot components. (Image: clogged-nozzle.webp)

Adjusting Temperature Settings

Experimenting with the temperature settings is often necessary. Start by setting the nozzle temperature within the recommended range for your filament. If the clicking persists, slightly increase the temperature by 5-10 degrees Celsius and try again. Too high a temperature can lead to filament degradation and other issues, so avoid excessive increases. Monitor the filament flow during printing. If the filament is not flowing smoothly, the temperature may be too low. If it’s oozing out or stringing, it might be too high. Make small adjustments and observe the results. Fine-tuning the temperature settings can greatly improve print quality. (Image: adjusting-temperature.webp)

Calibrating the Extruder Steps

Incorrect extruder steps can also cause clicking. This involves calibrating the number of steps the extruder motor takes to push a specific length of filament. The steps per millimeter (E-steps) value in your printer’s firmware needs to be correct. Measure a known length of filament, say 100mm, and mark it. Then, command the printer to extrude that length. Measure how much filament was actually extruded and compare it to your target (100mm). If it’s different, calculate the new E-steps value and update your firmware. Calibrating E-steps ensures that the printer feeds the correct amount of filament, preventing under-extrusion or over-extrusion. Proper calibration is crucial for overall print accuracy.

Preventative Measures

Preventing extruder clicking is often easier than fixing it. By taking some precautions, you can reduce the likelihood of this issue occurring. Regular maintenance and proper filament handling are key. Proactive steps can save you time and frustration. Establishing good habits ensures that your printer operates smoothly and consistently. These preventative measures enhance the longevity of your printer.

Proper Filament Storage

Store your filament in a dry, cool place. Filament absorbs moisture from the air, which can lead to clogging and extruder clicking. Using airtight containers or desiccant packs can help keep your filament dry. Avoid storing filament in humid environments, like basements. Moisture absorption can cause the filament to bubble during printing, affecting quality. Proper storage preserves the quality of the filament. Protecting your filament from dust is also advisable. (Image: filament-storage.webp)

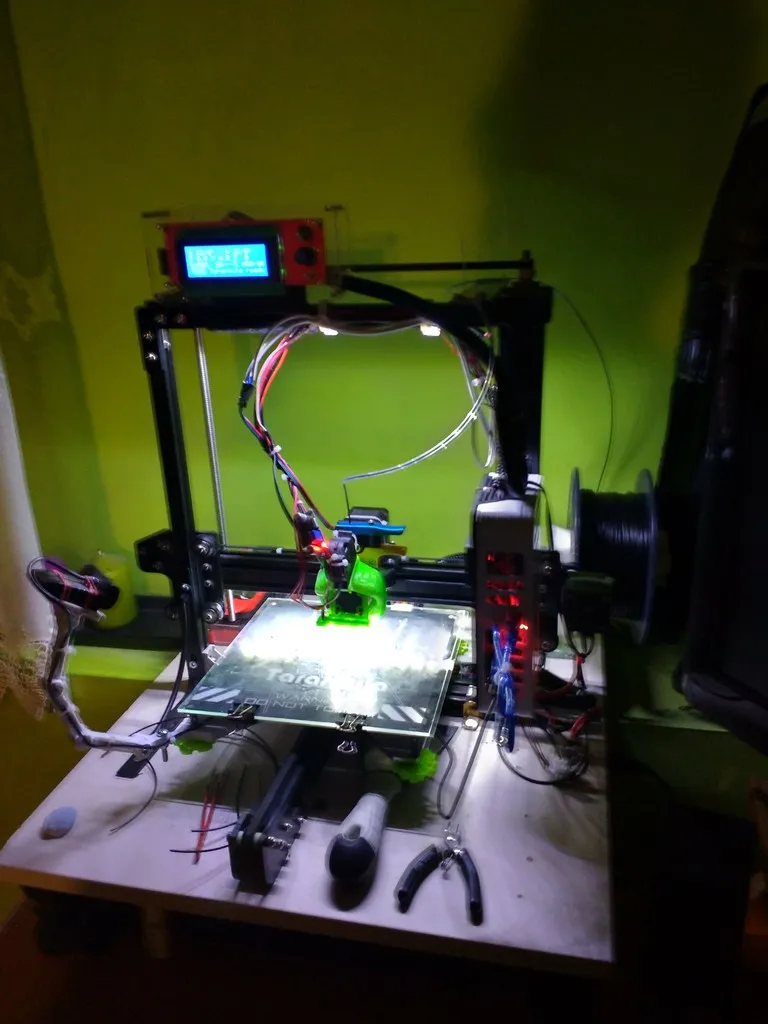

Regular Maintenance

Perform regular maintenance on your Tevo Tarantula. This includes cleaning the nozzle, checking and tightening belts and screws, and lubricating moving parts. Regularly inspect the hot end for any signs of damage or wear. Keep your printer clean and free from dust and debris. Regular maintenance helps prevent many common issues, including extruder clicking. This can prolong the life of your printer. Proper maintenance includes a good cleaning routine after printing. (Image: extruder-maintenance.webp)

Choosing the Right Filament

Choosing high-quality filament is crucial. Opt for reputable brands known for consistent diameter and quality. Avoid buying filament that is old or has been stored improperly. Read reviews and choose filaments that are compatible with your printer. Experiment with different filament types to find the ones that work best for your projects. Consider the material properties of the filament, such as its melting point and flexibility. The right filament choice can significantly improve print quality.

Conclusion

Extruder clicking on the Tevo Tarantula can be frustrating, but it is a common problem with readily available solutions. By understanding the causes, troubleshooting systematically, and taking preventative measures, you can keep your printer running smoothly. Remember to check your filament, nozzle, and temperature settings. Regular maintenance and the use of high-quality filament will minimize issues. With these tips, you’ll be able to fix the clicking and return to successful 3D printing. Happy printing!